DAIRY PRODUCTS

Delivering nutrition, health, and deliciousness with Mayekawa’s temperature control technology

Better for you, your customers

and the environment

-

Temperature that ensures quality

Precise control of temperatures that affect product quality

-

Reduce CO2 emissions

Design highly energy-efficient facilities

-

Improve productivity

Long-term continuous operation of the hardening process is possible

Holistic temperature and energy management

The diversification of dairy products such as ice cream, yogurt, butter, and cheese is increasing in response to changing lifestyles and growing interest in high nutritional value. A lot of energy is consumed in the processes related to the manufacturing of such products. In order to reduce this consumption, designing a system that is based on thermal balance and temperature conditions on the process side is effective.

Based on a comprehensive understanding of the entire production process from receiving raw milk to manufacturing, storing, and shipping the finished product, Mayekawa offers cooling systems that realize optimal heat energy consumption in line with the required load. We also support and service existing facilities so that they can always operate efficiently through attentive maintenance.

Stable, high-efficiency cooling at all times for fluctuating process loads

Almost all dairy factories use large amounts of low-temperature chilled water on a daily basis for storage tank and post-sterilization cooling. In producing this chilled water, electricity used by the refrigerators cooling it accounts for a large portion of the energy consumed. In order to increase the efficiency of the chilled water production process by supplying lower and more stable temperatures, Mayekawa offers super-cooling systems that utilize slurry ice. Additionally, by utilizing our extensive know-how to optimally combine equipment such as highly efficient high-temperature chillers and heat pumps according to the process heat load, we can design and construct cooling systems that fully satisfy client needs.

Utilizing both heat and cooling energy with a heat pump

In addition to large quantities of cooling energy, dairy product manufacturing processes also use heat energy in the product heating process. This heat is mostly produced via steam; thus, running costs fluctuate significantly according to changes in crude oil prices. As both heating and cooling are repeatedly carried out in the production process, our experience tells us that the amount of heat and cooling generated in each process is approximately the same. Thus, Mayekawa’s heat pump system reduces CO2 emissions and saves energy in the yogurt production process.

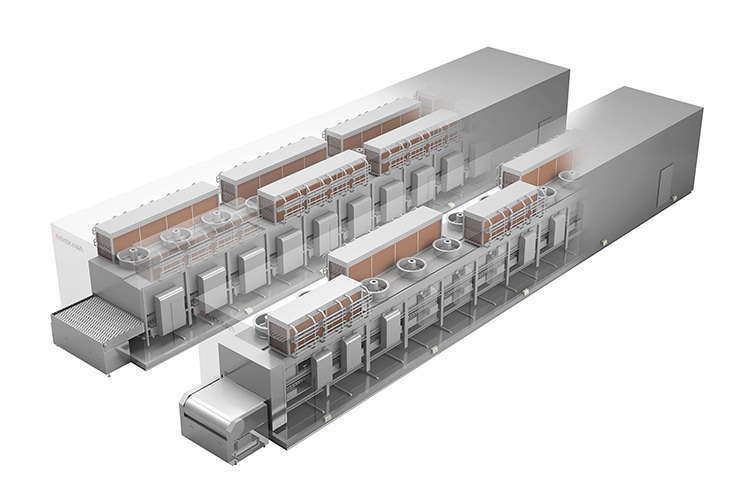

Ice cream hardening tunnel

In order to stabilize the quality of smooth ice cream that has undergone aging and freezing processes, it is important to quickly cool and harden it to -30°C (-22°F) after filling. Mayekawa has an extensive lineup of hardening tunnels, including spiral and straight types, allowing clients to choose the best solution for their space and production volume needs.

Dehumidification function that makes the continuous operation of the hardening process possible

Installing the optional long-term operation system (LTO) that controls the amount of moisture in the hardening tunnel through dehumidification and by removing and collecting frost, enables continuous operation for up to six days without having to reduce hardening tunnel capacity or stop for defrosting even if the internal temperature is -45°C (-49°F). Mayekawa can help you realize the increased production volume and reduced standby costs that can achieved through stable production management.

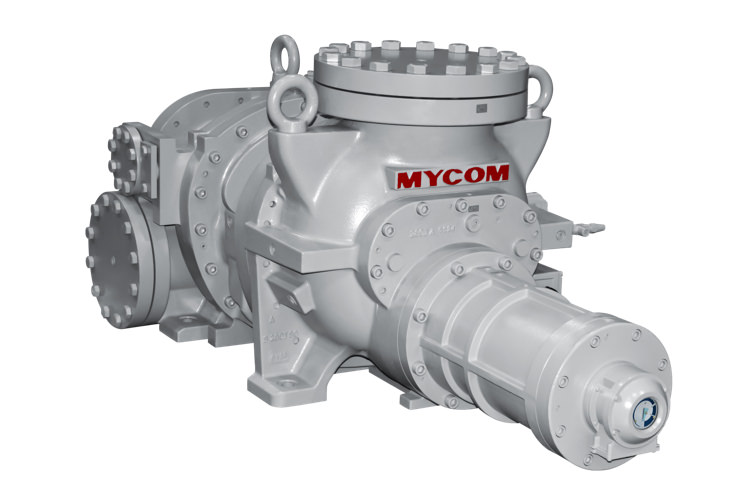

Refrigeration system for ice cream hardening

The ice cream hardening tunnel heat source component has an NH3/CO2 cascade refrigeration system that can manufacture products using CO2 refrigerant at -50°C (-58°F). Even when dealing with a wide variety of product loads, the number of compressors and rotations speeds are controlled; thus, efficient cooling of multiple pieces of hardening equipment that have different cooling loads and operational starts/stops is achieved. Additionally, we offer cooling systems that achieve both efficiency and ease of use, such as the NewTon i, a specialty system designed for ice cream on sticks that uses calcium chloride brine and can be used for a long period of time without rusting.