Brine & Water chillers

For both improved efficiency and environmental sustainability, industrial-use refrigeration systems are increasingly using natural refrigerants. At Mayekawa, we design and manufacture a variety of brine chillers built around the MYCOM compressor. And we can design and build units best configured to your specific needs.

0°C + Chilling water

Chiller unit (natural refrigerant)

Chiller unit (natural refrigerant)

This is a chilled water circulation type refrigeration system that creates, supplies, and circulates water with a temperature of 0.5°C (33℉) to the refrigeration process at a food factory. It uses natural and environmentally friendly ammonia as a refrigerant. The amount used to fill the system is kept to a minimum, and the unit is constructed in a manner that prevents leakage outside of the unit or on the chilled water side. A large-bore SUS pipe is used for the chilled water pipe, which makes clogging difficult while also offering excellent cleaning characteristics.

SPECIFICATIONS

- Cooling capacity: MZCF-100 98kW (27.9TR), MCZ-200 197kW (56.7TR)

- Supplies chilled water from 0.5 to 2°C (33 to 36℉)

- Refrigerant: Ammonia (R717)

WHERE TO USE

- Poultry processing plants

- Food processing plants

Standard water-cooled ammonia chiller

mCHILLER FUGU

mCHILLER FUGU

The mCHILLER FUGU is a Mayekawa plug-and-play standard solution with a strong focus on energy consumption and the perfect balance between durability and simplicity. The compact mCHILLER FUGU is designed for easy and simple installation and a long lifespan. It utilizes a natural refrigerant, ammonia, for the highest energy efficiency, and the best sustainability. With an ammonia charge as low as 55 kg (122 lbs), the mCHILLER FUGU achieves a high level of safety.

The mCHILLER FUGU comes with a FAT Report (Factory Acceptance Test) that is performed at our factory. The FAT includes a full load thermal performance test, thermal imaging of key points, and vibration measurements.

SPECIFICATIONS

- Cooling capacity : 604 to 1302 kW (172 to 370TR) at 7°C (44℉) outlet/12°C (53℉) inlet

- Secondary media outlet from -12 to 12°C (10 to 53℉)

- Refrigerant: Ammonia (R717)

- Refrigerant charge: 55 to 92 kg (122 to 203 lbs)

WHERE TO USE

- Breweries and wineries

- Diaries and food processing

- Industrial processes

- Data centers

- Building comfort cooling

Standard air-cooled ammonia chillers

mCHILLER TAKA

mCHILLER TAKA

The new mCHILLER TAKA is a standard air-cooled ammonia chiller with a strong focus on energy consumption and safety. The perfect balance between high efficiency, durability, and simplicity.

This chiller is designed to meet the needs of semi-industrial and commercial markets such as data centers, process cooling, HVAC, etc. Depending on the application, the chillers will cover 80-300 kW as nominal refrigeration capacity.

With the mCHILLER TAKA, you are getting a low-charge ammonia chiller tailor-made as the perfect alternative to synthetic refrigerant chillers.

SPECIFICATIONS

- Cooling capacity :121 to 242 kW (34 to 69TR) at 7°C (44℉) outlet/12°C (53℉) inlet

- Secondary media outlet from -12 to 12°C (10 to 53℉)

- Refrigerant: Ammonia (R717)

- Refrigerant charge: 20 to 24 kg (44 to 53 lbs)

WHERE TO USE

HVAC

- Hospitals

- Hotels

- Office buildings

- Shopping Malls

- Data centers

Process cooling

- Food production

- Brewery

- Pharmaceutical production

- Dairy

Cold storage

- Slaughterhouse

Low charge ammonia chiller

Plate type evaporator + Microchannel condenser

The ammonia chiller system with microchannel condenser technology is the result of the extensive experience and technical foundation that characterize Mayekawa's reputation. Microchannel ammonia chiller was developed to meet real market needs, and this unit is different from its predecessors due to its compact structure. The plate type evaporator and microchannel condenser allow for exponential savings while cooling fluid(50% lower refrigerant charge); therefore, we have a strong, compact, safe and easy-to-use unit that also allows considerable equipment cost reduction.

SPECIFICATIONS

- Capacity : 140 to 263kW (40 to 75TR)

- Supplies chilled water from 7 to 12°C (44 to 53℉)

- Refrigerant: Ammonia (R717)

WHERE TO USE

- Beverages

- Winery

- Dairy products

- Food

- Chemical/Petrochemical

- Pharmaceutical

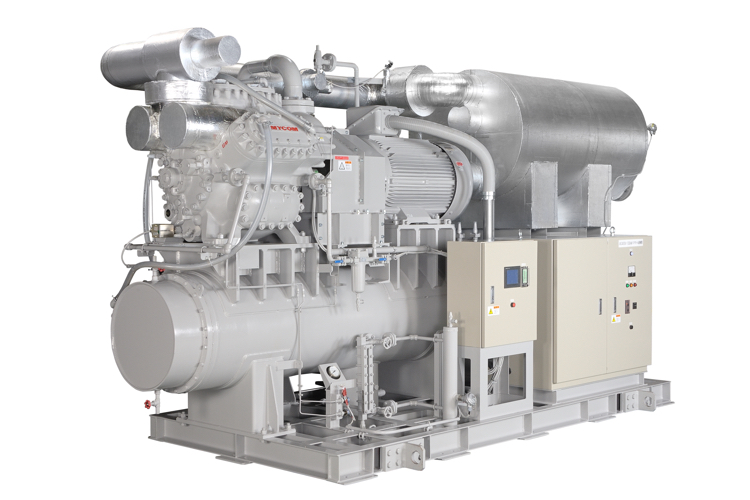

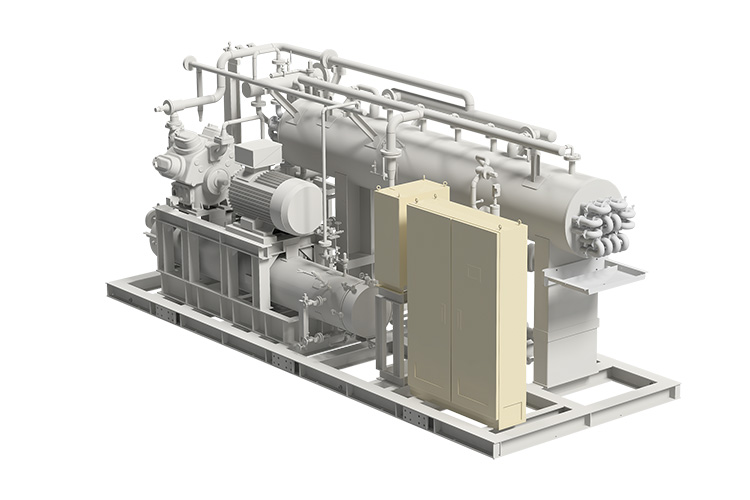

Glycol chiller

Glycol chiller

We offer a lineup of both reciprocating and screw-type chillers, providing applicable refrigeration solutions for various plant requirements. A variety of units are available to meet client needs, from refrigerant compatibility (ammonia, HFCs) to the liquefaction of various gases, process fluid cooling and explosion-proof specifications.

SPECIFICATIONS

- High-efficiency reciprocating glycol chiller

Cooling capacity: 80 to 1,140kW (22.7 to 324.1TR) *ammonia (R717)

Brine temperature: 5 to -20°C (41 to -4℉)

Refrigerant: ammonia (R717), HFCs, other - Reciprocating glycol chiller

Cooling capacity: 10 to 640kW (22.7 to 182.0TR) *ammonia (R717)

Brine outlet temperature: 5 to -35°C (41 to -31℉)

Refrigerant: ammonia (R717), HFCs, other - Reciprocating explosion-proof glycol chiller

Cooling capacity: 5 to 210kW (1.4 to 59.7TR)

Brine outlet temperature: 5 to -25°C (41 to -13℉)

Refrigerant: Propane, R404A - Screw-type glycol chiller

Cooling capacity: 10 to 2,750kW (2.8 to 781.8TR) *ammonia (R717)

Brine outlet temperature: 5 to -45°C (41 to -49℉)

Refrigerant: ammonia (R717), HFCs, other

WHERE TO USE

- Various types of industrial plants

- Food processing plants

Process cooling & refrigeration, ice pop hardening

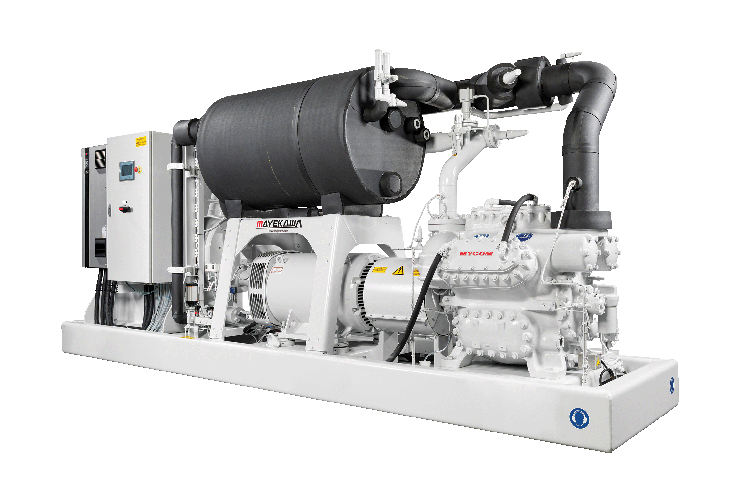

NewTon i/B - glycol chillers for process cooling

NewTon i

A brine chiller with all the benefits of the NewTon series, including high efficiency, safety, and environmental friendliness. It is safe because the brine solution cooled with ammonia is sent to the process side. The amount of ammonia used to fill the unit is kept to a minimum, and it uses a shell and plate heat exchanger and a screw compressor equipped with a semi-hermetic IPM motor that is leak-resistant. As existing brine piping can be used, construction costs for system renewal can also be kept low.

・NewTon B

Standard type NewTon for process cooling.

・NewTon i

A NewTon unit specially designed for ice pop hardening. The refrigeration system is equipped with a shell and plate evaporator that uses corrosion-resistant titanium in the heat exchange part that comes into contact with the aqueous calcium chloride solution.

SPECIFICATIONS

- NewTon i

Cooling capacity: 232.9kW (66.2TR) *In the case of cooling water at 32 ℃(90℉)

Brine temperature: CaCl2 -35℃ (-31℉)

Refrigerant: Primary Ammonia(R717), Secondary Brine(CaCl2)

Remote monitoring service - NewTon B

Cooling capacity: 195.1kW (55.5TR) *In the case of cooling water at 32 ℃(90℉)

Brine temperature: PG supply 8 to -15℃(46 to 5℉)

Refrigerant: Primary ammonia (R717), Secondary Enthylene glycol (EG) or propylene glycol (PG) brine

Remote monitoring service

WHERE TO USE

- NewTon i: Ice pop manufacturing processes

- NewTon B: Process cooling