AUTOMOBILE & MACHINE MANUFACTURER

Build a sustainable production system

Better for you, your customers

and the environment

-

Reduce CO2 emissions

Heat pump help to reduce CO2 Emissions

-

Reduce production costs

Grasp the heat using in the manufacturing process and effectively utilize waste heat

-

Ensure consistent cycle times

Optimize production processes through energy management

Sustainable production system support

Aiming for a sustainable society, many automobile manufacturers are working to reduce their greenhouse gas emissions. The scope of such efforts extends to assembly factories, parts factories, bodywork factories, as well as offices and laboratories.

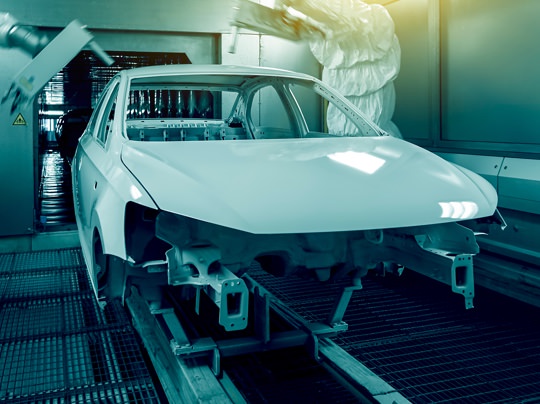

Among the varying processes inherent, painting and casting in particular have high CO2 emissions ratios. Thus, for automobile and parts factories that have equipment using fossil fuels to dry car bodies and parts on the painting line, Mayekawa recommends circulatory dehumidification systems and circulatory hot air heat pumps that use non-fluorocarbon refrigerants. Both of these contribute to energy saving and reduction of CO2 emissions by making effective use of heat.

If cold water from the heat pump is used for air conditioning in the workplace, it can also help improve the work environment. For environmental testing facilities, we also offer highly efficient cooling systems that contribute to reducing CO2 emissions while supporting environmental testing in low temperatures.

Environmental testing facilities for ensuring safety

At environmental testing facilities that recreate cold climates, Mayekawa’s highly efficient refrigeration systems can reproduce extremely low temperatures, such as -50°C. At facilities that recreate snowfall and ice burn environments, we can change the condition of the ice to create various situations, such conditions conducive to sliding, by utilizing the experience and know-how we have developed in making ice for skiing and ice skating. By supporting safety inspections in various environments such as these, Mayekawa contributes to improving mobility safety worldwide.

Heat pumps helps to reduce overall costs

For draining water and drying after the electrodeposition process on the painting line, as well as for drying after the application of lacquer, air for drying is heated by burning fossil fuels. Thus, by using a heat pump that uses factory waste heat as a heat source and by circulating the air, contributions to reduced CO2 emissions and energy consumption for heating can be achieved. Furthermore, if the air in the furnace that has been cooled with cold water from the heat pump is circulated, dehumidification and heating can be realized at the same time, contributing to a reduction in operating costs.

Air circulation heater

Optimize the drying process during printing

When drying film, etc., hot air is used in the drying process. This hot air is generated by burning fossil fuels. By using a heat pump that utilizes factory waste heat as the heat source, air is heated to generate hot air without burning fuels, realizing contributions to reduced energy consumption and CO2 emissions. Additionally, by controlling room temperature and humidity by using the cold water that can be simultaneously generated with hot air, cycle time variations resulting from the season in which drying takes place can be leveled, contributing to improved production efficiency.

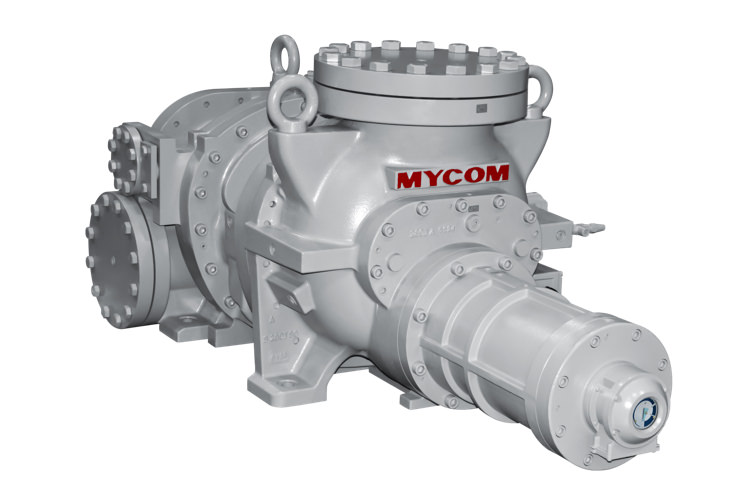

Hot air heat pump Ecosirocco

Our mission is to create a sustainable future by pursuing optimal systems,

equipment and technology while working side-by-side with customers.