Stories

Preventing production line stoppage by using every means possible

Mr. Brignardello

Among major Latin American countries, Chile boasts GDP per capita of the highest level. Mine development, and the export of agricultural, forestry, and fishery products that leverages the country’s rich natural environment, which includes the Andes Mountains and the Pacific Ocean, supports that growth.

At customers’ plants, if the refrigeration systems they use for freezing stop working during the harvest season, their production volume for that year will suffer a significant loss. Additionally, if they cannot store product at the proper temperature due to equipment failure, that product must be discarded. To ensure such things do not occur, proper maintenance activities are required to avoid sudden breakdowns and keep the plant in good operating conditions.

Up until the year 2000, Mayekawa Chile only had an office in Santiago. However, since then, it has been gradually increasing the number of offices it maintains beyond Santiago in order to provide a wide range of services to customers throughout the country, which spans a long distance north to south. This expanded presence brings customers peace of mind and allows them to concentrate on production activities.

Currently, the company maintains offices in Santiago, Curico, Concepcion, and Puerto Montt. In order to provide customers optimal support and solutions, employees visit their plants to better understand the requirements and production processes and ascertain the types of environments in which machinery is operating.

No matter how magnificent the plant or equipment is, unexpected failures may still occur

During the mussel harvest season of 2012, the Mayekawa Chile office in Santiago received a call from a customer. The customer was headquartered in Santiago and involved in aquaculture and processing products related to salmon, lobster, abalone, and mussels, among others, and exporting them to about 50 countries.

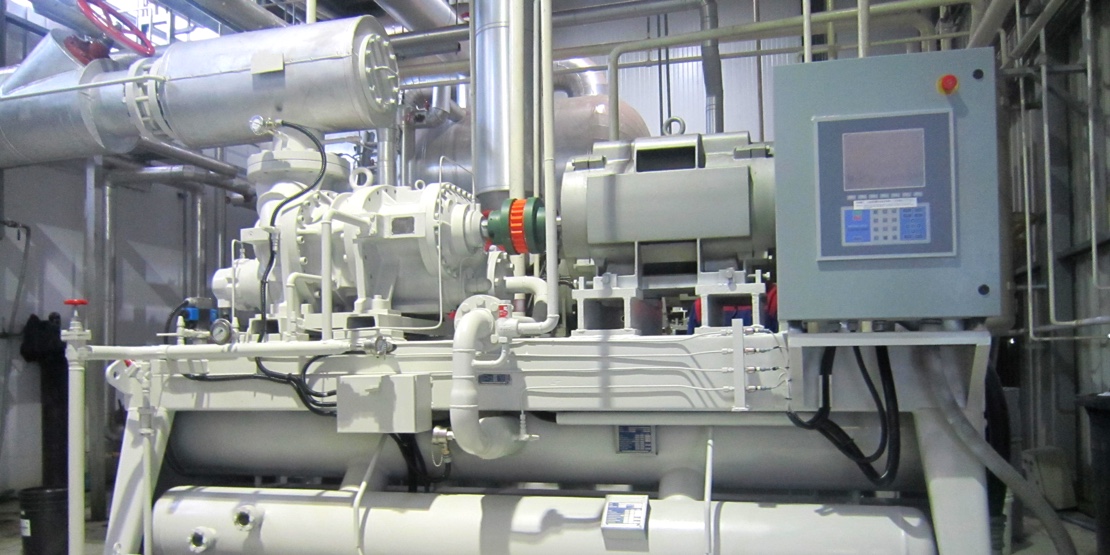

At the customer’s mussel processing plant on Chiloe Island, a refrigeration compressor manufactured by another company and used for mussel freezing processes suddenly stopped working. The company contacted the manufacturer of the compressor; however, they were informed that inventory and replacement parts were not readily available. The company now faced a critical situation wherein production would have to be stopped. If they could not restart processes quickly, they would miss the mussel harvesting period for that year. Thus, they contacted Mayekawa and asked for help in solving the problem.

As a compressor unit for a water chiller that Mayekawa had delivered to the same plant the previous year was operating smoothly, and because other plants operated by the customer were using Mayekawa equipment as well, they were familiar with Mayekawa.

Comprehensive technical knowledge was brought together for the challenge of quickly restoring operations in the shortest amount of time possible

Mr. Brignardello, a man who had been working for many years to expand the service network in Chile and deepen customer relationships, was the person who took at the call at the Santiago office. Understanding the urgency of the situation, he contacted a service technician at Mayekawa’s Puerto Montt office, the closest office to Chiloe Island, and they went to the plant in question.

After conducting a field survey, the service technician thought it might be possible to replace the compressor in the compressor unit made by the other company with a Mayekawa compressor. The compressor units made by the other company and Mayekawa have different ways of mounting their respective oil pans and oil tanks. Their ways of lubricating the units differ as well. Nonetheless, after comparing the datasheet from the other company with Mayekawa’s and making some calculations, it was confirmed that there would be no problem with swapping out the compressor.

Based on this survey, an estimate and work plan were submitted to the customer on the following day. According to the work plan, replacing the compressor and associated work for modifying the base and plumbing would be completed within five days. The aim was to restart the plant production line on the following Monday, one week after the field survey was conducted.

At the same time the plan was being created, the person in charge of construction proceeded to make arrangements for

materials and workers; they arrived at the plant four days later on the Thursday of the week in question and started

construction.

Moreover, for restarting the production within one week, a reliable contractor from Santiago, who would be capable of

dealing with unforeseen circumstances, was sent to the plant as well.

Everything needed for successful completion of the job, from workers to materials, was sent to Chiloe Island from Santiago, a distance of 1,300km. Though land routes were used to ship the tools the workers would use, they still needed to prepare in a short amount of time.

From their perspective, the customer was feeling doubts about whether production could really be restarted in one weeks’ time, taking into consideration the distance between Santiago and the plant, and the amount of time needed to complete the work. However, they had no other choice and entrusted Mayekawa to carry out the job. Although the Mayekawa side also had technical concerns, they were determined to take on the challenge from a desire to earn the customer’s trust.

Getting operations restarted as quickly as possible while further lengthening the plant’s life

In the end, the plant resumed operations on Monday as planned. Regarding the technical concerns, due to the comprehensive technical knowledge of the staff sent to the site, including that related to refrigeration systems, electricity, and compressors, the job was able to be completed without any major problems occurring.

The customer, who harbored serious doubts that production could be restarted within one week, was very surprised that the problem was resolved in such a short period.

Furthermore, the renewal of the existing unit was carried out at a lower cost and in a shorter period of time compared with what would be required if a new unit was purchased, and the life of the plant was extended as well.

The outcome was positively acknowledged by the customer, who later ordered and had two MYCOM compressors delivered to the same plant, both of which are currently operating smoothly.

Working together with clients as a trusted partners to support their production needs

“While using all available means to ensure customer satisfaction, we must work to meet customer needs and solve their problems as quickly and efficiently as possible, and provide them with optimal solutions in critical situations,” said Mr. Brignardello.

“What is the customer thinking? What do they need? What are their expectations? What is being sought from us is not only the provision of high-quality compressors and cooling equipment but also the role of a business partner supporting their high-quality production,” he added.

Regardless of the fact that this challenge was the first of its kind for Mayekawa Chile personnel, with this mindset, they were able to have production at the plant restarted in one week. With a goal of wanting to maintain high-quality products and services, all at Mayekawa work to build close relationships with customers in every kind of industry and support their businesses, regardless of whether or not they utilize MYCOM compressors. That is the stance adopted by Mayekawa Chile, which continues to take on the challenges presented by customers, presenting them with the best solutions for their needs.

We're ready to help, wherever you are

Our mission is to create a sustainable future by pursuing optimal systems,

equipment and technology while working

side-by-side with customers.