Poultry processing systems

Contributing to the automation and labor saving of the poultry production line.

Mayekawa is also responsible for the engineering of peripheral equipment, systems and production lines required for the process of poultry.

We propose an optimal system for the production line of poultry by combining technologies such as robot, production, control and energy-saving.

NECK SLITTER - automated chicken neck skin slitter

NECK SLITTER

Pre-processing machine before neck skin removing. Precise front skin slitting enables to remove neck skin in good shape in a subsequent processing by NECK SKIN REMOVER.

SPECIFICATIONS

- Capacity: 12,000 birds/hour, maximum*

*To be installed in an evisceration line.

WHERE TO USE

- Poultry processing plant

NECK SKIN REMOVER - automated chicken neck skin remover

NECK SKIN REMOVER

Neck skin is removed from the back side of the chicken. High yield and less damage on neck meat can be achieved by utilizing a similar process to hand cut.

SPECIFICATIONS

- Capacity: 12,000 birds/hour, maximum*

*To be installed in an evisceration line.

WHERE TO USE

- Poultry processing plant

GIZZARD OPENER

GIZZARD OPENER

Automatically incise and open gizzard to clean the interior. Equipped with the auxiliary skinner to help reduce the workload of the finishing process.

SPECIFICATIONS

- Capacity: 4,500 pieces/hour, maximum

Equipped with the auxiliary skinner

WHERE TO USE

- Poultry processing plant

HALVIDAS - chicken cut up systems

HALVIDAS

In the chicken disassembly process, chicken is first cut into three parts: front half (upper half), bone-in leg, and hip bone. All of these processes are processed automatically by a single machine.

SPECIFICATIONS

- Capacity: 2,700 birds/hour, maximum

Equivalent yield and shape of output to those of manual deboning.

WHERE TO USE

- Poultry processing plant

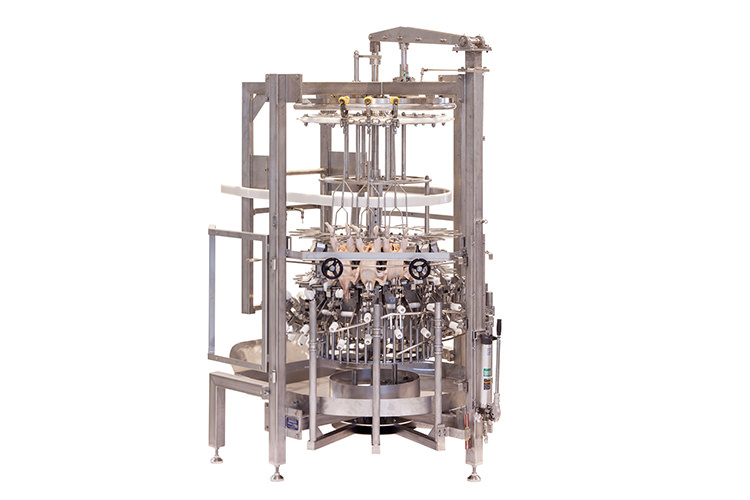

AUTOMYDAS II - fully automated combination weighing systems

AUTOMYDAS

With full automation of optimal weighing.

Products of different sizes and weights transported from the conveyor are automatically loaded, combined to meet the target weight, and sequentially unloaded. Better combination for better yield is achieved.

SPECIFICATIONS

- Capacity: 24 packages, per 2kg (4lb)/min, maximum

WHERE TO USE

- Poultry processing plant