An industrial use refrigeration system has a lifespan of several decades.

Precisely because you will rely on this equipment for a long time,

it must always live up to your expectations.

Where is the world heading? How will the cold chain alter? How will your business develop?

In order to respond to these needs,

based on the concepts of natural refrigerants, energy saving, and ease of use,

we at Mayekawa drew on all the technologies that we had developed

to create a part of the future.

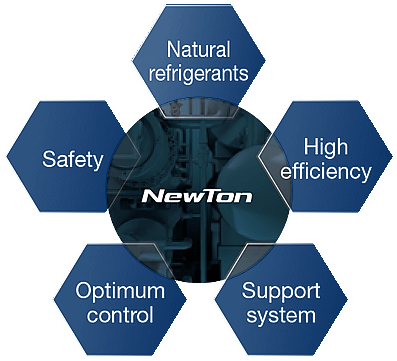

This is NewTon.

NewTon concept movie

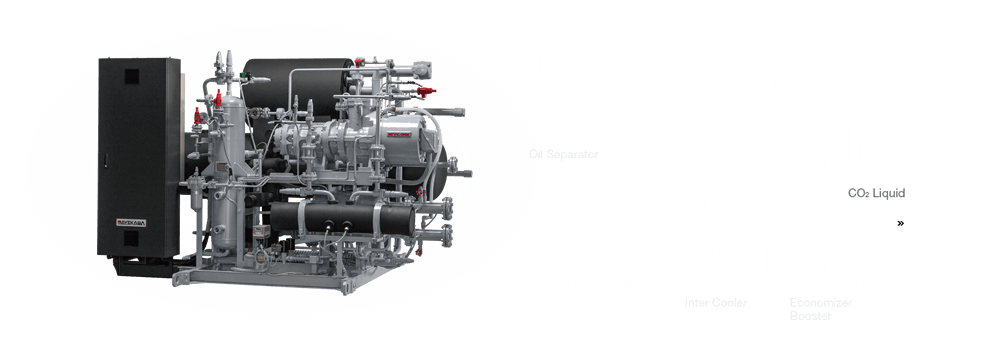

Natural refrigerants

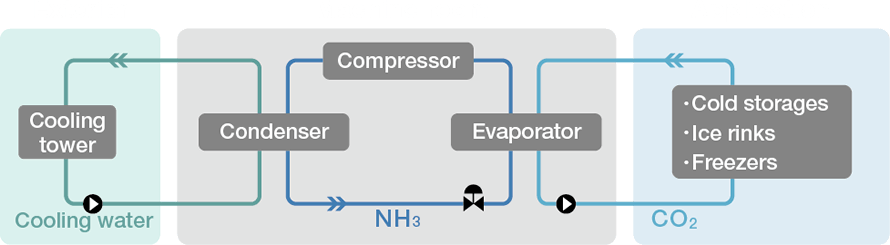

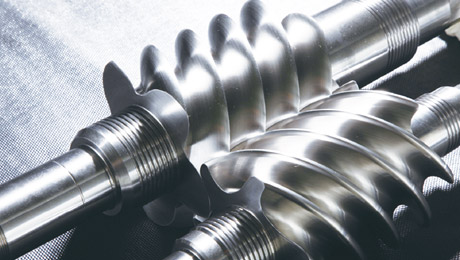

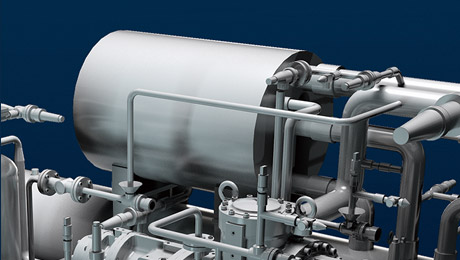

Ammonia refrigerant, the most thermodynamically efficient refrigerant, is used as a primary refrigerant. CO2, which is safe, has excellent cooling capability, and a very low transport power is used as the secondary refrigerant supplied to air coolers that keep the inside of cold storage warehouses cold.

Safety

Ammonia refrigerant can be used across a wide range of temperatures, and is noteworthy for its high level of thermal efficiency. However, it is also poisonous and flammable, making it a difficult medium to handle. NewTon uses an absolute minimum charge of ammonia refrigerant in a leak-resistant construction. For the CO2 secondary refrigerant, welded joints are used whenever possible to form a sealed structure and prevent leaks. Safety is ensured via CO2 concentration sensors installed in cold storage and work areas to alert workers in case of emergency.

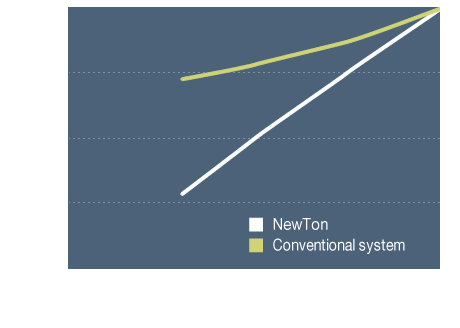

High efficiency

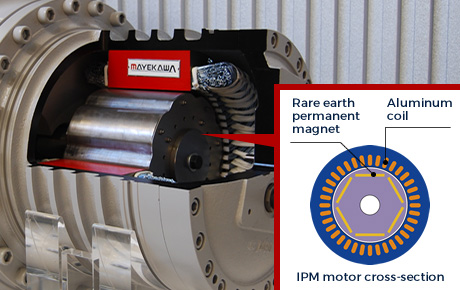

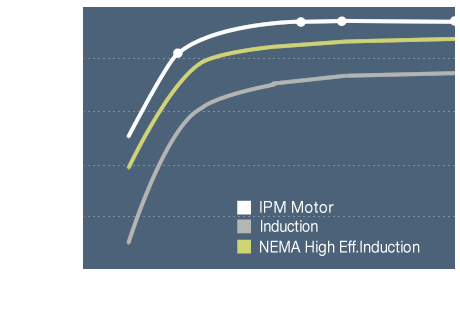

NewTon system consists of new design of compressor with IPM motor, optimal design of heat exchanger. In addition the freezing cycle has new idea.

All of the features that make up the NewTon system operate at top efficiency. This is particularly evident where 60 to 70% of electricity used in cold storage is consumed by cooling equipment. NewTon significantly reduces the amount of power used in cooling equipment, passing on amazing energy efficient benefits to the customer.

Optimum control

A design tailored to the specific application is the reason NewTon always provides the best possible performance. Cooling systems require different temperatures, features, and operating times according to the application.

Mayekawa is well-versed in the particulars of nearly every application, including cold storage facilities, ice production, ice rinks, food product freezing and many more. This wealth of experience gives us the ability to customize designs. Even with significant variations in function, or load, the NewTon provides worry free operation.

Support system

We provide maintenance service that no one else can, with a full menu of options from development to production, sales, installation and service.

Facilities have a lifespan of a few dozen years. To ensure optimum operating efficiency that is as good as the day the equipment was installed, a remote monitoring network keeps watch over operating status from the plant where it was manufactured. The system identifies abnormal data to help prevent problems before they occur.