Proven energy efficiency

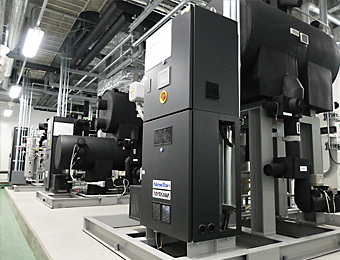

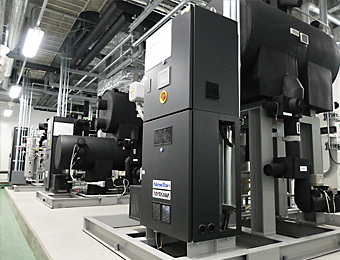

“At first I was skeptical, thinking that an NH3/CO2 indirect cooling system might not be as efficient as the conventional liquid ammonia pump system,” says Mr. Sasaki from Yokorei’s technology department. However, after viewing actual NewTon operating data, those concerns gradually went away. CO2 is a high-performance refrigerant, and there is an extremely small difference between the evaporation temperature of ammonia and condensation temperature of CO2. The system’s flooded-type evaporator on the cascade condenser is resistant to load fluctuation and is maintained and operated on an extremely low superheat value. These factors convinced Mr. Sasaki of NewTon’s superior energy efficiency. He went on to praise the energy efficiency of the NewTon system, saying that its core technology of the IPM motor and inverter were the best possible match for a refrigeration system of this size.

Power consumption reduction by 38 %

The NewTon system’s energy efficiency has shown improvements at the Yumeshima Logistics Center, operating on approximately 38% less power than similar-sized CFC systems. Mr. Sasaki expresses his surprise, saying, “The direct-expansion R-22 hairpin coil system we have been using does not require fan power for the evaporator, and is an extremely energy-efficient system. However, NewTon performance exceeds even this.”

The economic benefits of the NewTon system do not stop with reduced electrical power consumption.

“Factory Packaged Systems reduce the need for maintenance areas, and there is no longer any need to flush the oil. Additionally, because the ammonia leak detector is only required in the machine room, maintenance costs are significantly reduced,” says Mr. Sasaki.

Consideration to safety

Another factor that makes the NewTon system so reliable is its safety. Sasaki comments on this, saying, “The ammonia charge is significantly smaller than similarly-sized liquid ammonia pump systems. Because the ammonia equipment is contained within the machine room, facility managers can rest assured that any accidents are limited to that space only. A benefit of the flooded-type cascade condenser is that it helps prevent liquid flood back into the compressor.”

Another factor that makes the NewTon system so reliable is its safety. Sasaki comments on this, saying, “The ammonia charge is significantly smaller than similarly-sized liquid ammonia pump systems. Because the ammonia equipment is contained within the machine room, facility managers can rest assured that any accidents are limited to that space only. A benefit of the flooded-type cascade condenser is that it helps prevent liquid flood back into the compressor.”

There are no concerns as a CO2 refrigerant recycling system. Because the system keeps CO2 refrigerant pressure from rising when the equipment is turned off, users have peace of mind when leaving the equipment off for long periods of time. “NewTon offers superb protection of the CO2 circulation system, preventing CO2 refrigerant from turning into dry ice and overcooling, a feature that was not available on any previous systems,” mentions Sasaki.

These results have convinced Yokorei to install the NewTon system in other locations in the future, with plans to bring the NewTon R-3000 into non-Japanese subsidiaries as well, including Thai Yokorei and the Bangpakong Distribution Center2.

(Interviewed March 2015)

Company Profile

YOKOHAMA REITO CO.,LTD.

Since its foundation in Yokohama in 1948, Yokorei has dedicated their business to cold storage facility logistics and food product sales. Their contribution to food safety and its consumers has earned an excellent reputation in the industry.

The new Yumeshima Logistics Center was built in Osaka's Special Economic Zone, functioning as both a port and distribution center with the latest technologies and an environmentally-friendly design.

Other Case Studies

Enables safer operation and a management control system with less need for manpower to deliver fresh and safe halal food.

Food supplier

Use: Cold storage, freezer

Solves long-standing noise problems. Operates so quietly you must open the door to the machine case to hear it running.

Bakery

Use: Freezer

Operation status is constantly available in real-time. Maintenance contract improves operation and reduces need for manpower.

Distribution center

Use: Cold storage

Another factor that makes the NewTon system so reliable is its safety. Sasaki comments on this, saying, “The ammonia charge is significantly smaller than similarly-sized liquid ammonia pump systems. Because the ammonia equipment is contained within the machine room, facility managers can rest assured that any accidents are limited to that space only. A benefit of the flooded-type cascade condenser is that it helps prevent liquid flood back into the compressor.”

Another factor that makes the NewTon system so reliable is its safety. Sasaki comments on this, saying, “The ammonia charge is significantly smaller than similarly-sized liquid ammonia pump systems. Because the ammonia equipment is contained within the machine room, facility managers can rest assured that any accidents are limited to that space only. A benefit of the flooded-type cascade condenser is that it helps prevent liquid flood back into the compressor.”